General UPS Questions

1: It is not UL tested. Therefore, should something go wrong and damages be caused to your connected equipment, APC would not honor the claim. (Underwriters Laboratories Inc. [UL] is an independent, not-for-profit product safety testing and certification organization)

2: This configuration does not provide any extra surge protection. The UPS is designed to remove any possibility of a surge reaching the output recepticles. If a surge, strong enough to damage equipment was received, the first UPS in the chain would sacrifice itself to protect it’s load. This would mean that power would be removed from the 2nd UPS in the chain and force it to battery.

3: Whenever connecting a 2nd UPS into a 1st UPS, the chance of Overloading the 1st UPS is greatly increased. The amount of receptacles in a UPS are restricted. This is due to the power limitations of the UPS itself. Although, the amount of receptacles has been increased, the overall Watt capacity of the 1st UPS remains the same. The capability of the 2nd UPS, will be inversely affected by that of the 1st UPS. Therefore, the overall Watt capacity of the configuration is no greater than that of the 1st UPS in line.

4: In most cases, daisy-chaining UPSs does not allow for extra run time. If you are using a UPS that outputs a step-approximated sine wave when on battery, as soon as the fist UPS goes on battery, the second UPS will also go on battery because it will see the step- approximated sine wave as distorted or bad power. Both units will discharge together, and will not provide any extra run-time to the load.

If you are looking for extra run-time, we recommend one of our Smart-UPS XL products, which have the capability of adding extra, external battery packs.

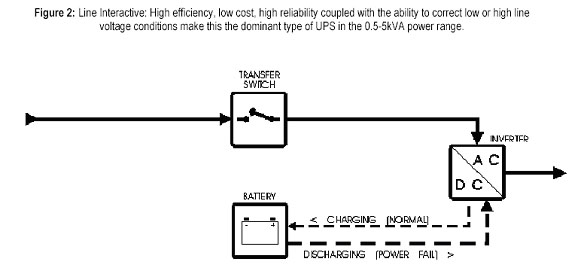

When the input power fails, the transfer switch opens and the power flows from the battery to the UPS output. With the inverter always on and connected to the output, this design provides additional filtering and yields reduced switching transients when compared with the Standby UPS topology.

In addition, the Line Interactive design usually incorporates a tap-changing transformer. This adds voltage regulation by adjusting transformer taps as the input voltage varies. Voltage regulation is an important feature when low voltage conditions exist, otherwise the UPS would transfer to battery and then eventually down the load. This more frequent battery usage can cause premature battery failure. However, the inverter can also be designed such that its failure will still permit power flow from the AC input to the output, which eliminates the potential of single point failure and effectively provides for two independent power paths. This topology is inherently very efficient which leads to high reliability while at the same time providing superior power protection.

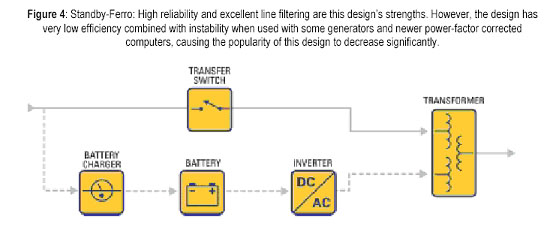

In the Standby-Ferro design, the inverter is in the standby mode, and is energized when the input power fails and the transfer switch is opened. The transformer has a special “Ferro-resonant” capability, which provides limited voltage regulation and output waveform “shaping”. The isolation from AC power transients provided by the Ferro transformer is as good or better than any filter available. But the Ferro transformer itself creates severe output voltage distortion and transients, which can be worse than a poor AC connection. Even though it is a standby UPS by design, the Standby-Ferro generates a great deal of heat because the Ferro-resonant transformer is inherently inefficient. These transformers are also large relative to regular isolation transformers; so standby-Ferro UPS are generally quite large and heavy.

Standby-Ferro UPS systems are frequently represented as On-Line units, even though they have a transfer switch, the inverter operates in the standby mode, and they exhibit a transfer characteristic during an AC power failure. Figure 4 illustrates this Standby-Ferro topology.

The principal reason why Standby-Ferro UPS systems are no longer commonly used is that they can be fundamentally unstable when operating a modern computer power supply load. All large servers and routers use “Power Factor Corrected” power supplies which present a negative input resistance over some frequency range; when coupled with the relatively high and resonant impedance of the Ferro transformer, this can give rise to spontaneous and damaging oscillations.

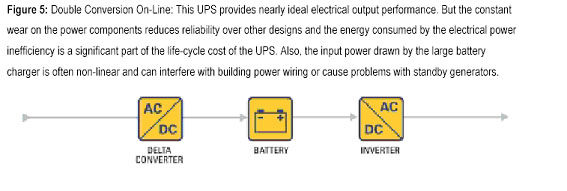

In the Double Conversion On-Line design, failure of the input AC does not cause activation of the transfer switch, because the input AC is NOT the primary source, but is rather the backup source. Therefore, during an input AC power failure, on-line operation results in no transfer time.

The on-line mode of operation exhibits a transfer time when the power from the primary battery charger / battery / inverter power path fails. This can occur when any of the blocks in this power path fail. The inverter power can also drop out briefly, causing a transfer, if the inverter is subjected to sudden load changes or internal control problems.

Double Conversion On-Line UPS systems do exhibit a transfer time, but under different conditions than a standby or line interactive UPS. While a Standby and Line Interactive UPS will exhibit a transfer time when a blackout occurs, a double conversion on-line UPS will exhibit a transfer time when there is a large load step or inrush current. This transfer time is the result of transferring the load from the UPS inverter to the bypass line. Generally, this bypass line is built with dual Silicon Controlled Rectifiers (SCRs). These solid state switches are very fast, so similar to the Standby and Line Interactive UPS, the transfer time is very brief, usually 4-6 milliseconds.

Both the battery charger and the inverter convert the entire load power flow in this design, which causes reduced efficiency and increased heat generation.

A simple way to understand the energy efficiency of the delta conversion topology is to consider the energy required to deliver a package from the 4th floor to the 5th floor of a building as shown in Figure 7. Delta Conversion technology saves energy by carrying the package only the difference (delta) between the starting and ending points. The Double Conversion On-Line UPS converts the power to the battery and back again whereas the Delta Converter moves components of the power from input to the output.

In the Delta Conversion On-Line design, the Delta Converter acts with dual purposes. The first is to control the input power characteristics. This active front end draws power in a sinusoidal manner, minimizing harmonics reflected onto the utility. This ensures optimal conditions for utility lines and generator systems and reduces heating and system wear in the power distribution system. The second function of the Delta Converter is to charge the battery of the UPS by drawing power and converting it to the appropriate DC charging voltage.

The Delta Conversion On-Line UPS provides the same output characteristics as the Double Conversion On-Line design. However, the input characteristics are extremely different. With full Power Factor Correction, the delta conversion on-line design provides both input power control and output power control. The most important benefit is a significant reduction in energy losses. The input power control also makes the UPS compatible with all generator sets and reduces the need for wiring and generator oversizing. Delta Conversion On-Line technology is the only core UPS technology today protected by patents and is therefore not likely to be available from a broad range of UPS suppliers.

The power drawn by computing equipment is expressed in Watts or Volt-Amps (VA). The power in Watts is the real power drawn by the equipment. Volt-Amps is called the “apparent power” and is the product of the voltage applied to the equipment times the current drawn by the equipment.

Both Watt and VA ratings have a use and purpose. The Watt rating determines the actual power purchased from the utility company and the heat loading generated by the equipment. The VA rating is used for sizing wiring and circuit breakers.

The VA and Watt ratings for some types of electrical loads, like incandescent light bulbs, are identical. However, for computer equipment the Watt and VA ratings can differ significantly, with the VA rating always being equal to or larger than the Watt rating. The ratio of the Watt to VA rating is called the “Power Factor” and is expressed either as a number (i.e. 0.7) or a percentage (i.e. 70%).

The power rating of the UPS: UPS have both Watt ratings and VA ratings. Neither the Watt nor the VA rating of a UPS may be exceeded. In most cases, UPS manufacturers only publish the VA rating of the UPS. However, it is a standard in the industry that the Watt rating is approximately 60% of the VA rating, this being the typical power factor of common loads. Therefore, it is safe to assume that the Watt rating of the UPS is 60% of the published VA rating.

How to avoid sizing errors: Equipment nameplate ratings are often in VA, which makes it difficult to know the Watt ratings. If using equipment nameplate ratings for sizing, a user might configure a system which appears to be correctly sized based on VA ratings but actually exceeds the UPS Watt rating.

By sizing the VA rating of a load to be no greater than 60% of the VA rating of the UPS, it is impossible to exceed the Watt rating of the UPS. Therefore, unless you have high certainty of the Watt ratings of the loads, the safest approach is to keep the sum of the load nameplate ratings below 60% of the UPS VA rating. Note that this conservative sizing approach will typically give rise to an oversized UPS and a larger run time than expected. If optimization of the system and an accurate run time are required, discuss your requirements with RefurbUPS Power protection representative, for product recommendations to meet your needs.

Power consumption information on computer loads is often not specified in a way that allows simple sizing of a UPS. It is possible to configure systems that appear to be correctly sized but actually overload the UPS. By slightly over sizing the UPS compared with the nameplate ratings of the equipment, proper operation of the system is ensured. Over sizing also provides the side benefit of providing additional UPS backup time.

Background: Earth leakage monitors measure the resistance between phase (hot) and any current-carrying component to ensure that resistance remains high. Leakage current is typically measured by breaking the ground connection back to the mains and inserting a specific load that simulates a person interrupting the ground. Devices without a ground are highly insulated, and therefore the missing ground is not an issue during normal operation. However, were the device to become energized due to a fault or failure, it would look for a way to deflect the current to ground. Without a ground present, the current would take the path of least resistance. This would be hazardous as the return path may be through the load itself, a data line, or even a person.

In 120 Vac environments, each electrical device must reference the same ground which originates at the main service panel. Additionally, a properly grounded chassis acts as a filter against EMI/RFI interference. If this ground reference were missing, the EMI/RFI interference may result in erratic behavior of the device.

Certain types of data communication systems require a reference to ground. Additionally, some data lines use the ground as a shield against noise. RS-232, and other data cables, rely on ground to provide a return reference for the signal (although this is not the case with isolated data systems such as Ethernet). Without a ground, the signal will attenuate.

These models and product families include:

- PowerCell

- Back-UPS

- Powerstack

- Smart-UPS V/S

- Smart-UPS 620

Note: This discussion is a result of the fact that a Non-True RMS meter will read anywhere from 80 – 90 Vac from the output of a 120 Vac APC UPS (or 170 – 180 Vac from the output of a 230 Vac APC UPS) producing a stepped approximated sine wave while operating on- battery. This is not an issue when the UPS is operating on-line.

Smart-UPS (SU700 or higher), Matrix-UPS, Symmetra and Silcon product families produce a pure sine when operating on battery.

There are generally two types of meters: “Average responding” and “True RMS” meters. Average responding meters are more commonly used. True RMS meters tend to be more expensive. If the meter does not have “TRUE RMS” written right on the front, it is most likely NOT a True RMS meter.

The issue that arises with a non-True RMS or average responding meter is whether it is measuring the output from a linear load or a nonlinear load.

Linear loads include but are not limited to devices such as light bulbs, incandescent lamps and resistive heaters. Nonlinear loads include devices like computers. When measuring the output of nonlinear loads, the average responding meter will typically read LOW. True-RMS meters are most effective when measuring environments with harmonics. When a waveform is distorted from a standard sine wave (“the fundamental”), an average responding meter may produce readings that are misleadingly incorrect. A stepped approximated sine wave appears distorted when compared to a true sine wave; therefore, a reading will produce incorrect results.

When an average responding meter is measuring the stepped approximated output from an APC UPS while operating on battery, this meter will also read low. The wave shape generated is similar to what the meter would see from a nonlinear load, hence the averaging calculation that the meter makes will be miscalculated.

The following is a list of APC Accessories that may be upgraded. However, certain accessories may need to be serviced by APC due to safety issues.

| Part Number | Upgrade Information | |

| SmartSlot Call-UPS II | AP9608 | No upgrade available |

| SmartSlot Interface Expander | AP9607 | No upgrade available |

| SmartSlot Measure-UPS II | AP9612 | No upgrade available |

| SmartSlot Relay I/O Module | AP9610 | No upgrade available |

| SmartSlot SNMP Adapter for 10Base-T | AP9605 | No upgrade available |

| SmartSlot SNMP Adapter for Token Ring | AP9603 | No upgrade available |

| SmartSlot Triple Chassis | AP9604 | No upgrade available |

| SmartSlot Triple Chassis for Silcon | AP9604S AP904SR | No upgrade available |

| Web/SNMP Management Card | AP9606 | Firmware upgrades are available under the Support section of www.apcc.com. |

| Network Management Card | AP9617, AP9618, AP9619 | Firmware upgrades are available under the Support section of www.apcc.com |

| PowerView | AP9215 | No upgrade available |

| Share-UPS | AP9207 | No upgrade available |

In order to contact APC for information, please call 1-800-555-2725.

Users often have questions regarding the amperage draw of the load versus what the circuit is capable of supplying. According to National Electric Code, continuous loads (like an UPS operating continuously longer than three hours per day) must not exceed 80 percent of the branch-circuit overcurrent device (e.g. fuse or circuit breaker) rating. The following is taken directly from Article 210-23 of the 1995 National Electric Code Handbook (7th Edition):

Free, restricted access to the 2005 NEC online (Must register with the NFPA to access this document.)

APC UPS Units

1. APC Back-UPS have stepped approximated sine wave while the APC Smart-UPS have pure sine wave output. This means that APC Smart-UPS provide cleaner power to electronics and will function properly off of a generator. While APC Back-UPS will only marginally adjust input power to output power within a range, meaning sensitive electronics like motors will not function properly and it will not provide good output off of a generator with oscillating sine waves.

2. APC Back-UPS do not support network management cards. APC Smart-UPS do for most models except for example the APC SC series. These Network Management Cards allow for remote shutdown and power control.

3. APC Back-UPS have surge only outlets and battery backup/surge outlets while APC Smart-UPS only has battery backup/surge outlets. This means that APC Back-UPS can have an appliance plugged into a surge only outlet that could draw more power that the VA capacity that the UPS is rated for battery protection, such as a Printer.

These are the primary differences but some models vary in configuration and functionality when looking at the different APC Smart-UPS series.

1. Are capable of using Extended Run Battery Packs.

2. Can only use APC Network Management Card 2 SNMP management cards.

3. Have an LCD control panel with configurable options.

1. Are capable of using Extended Run Battery Packs.

2. Can only use APC Network Management Card 2 SNMP management cards.

3. Have an LCD control panel with configurable options.

1. Are Double Conversion Online UPS, meaning that the UPS is running on the battery at all times. This means there is not transition time at all when an interruption to power happens.

2. Are Capable of both Rack Mountable and Tower configurations.

1. Are Double Conversion Online UPS, meaning that the UPS is running on the battery at all times. This means there is not transition time at all when an interruption to power happens.

2. Are Capable of both Rack Mountable and Tower configurations.

Back-UPS & Back-UPS Pro/Office

1) Battery connection is loose or disconnected – If the battery connection is not secure the battery power will be unreliable. Verify that the internal battey connections are secure.

2) Unit is Overloaded – Each UPS is limited in the amount of equipment that can be plugged into it. The number in the model number of the UPS tells you the Volt-Amp (VA) limit of your specific model. (The exact model number can be found on a white bar-code sticker on the rear of the unit.) For example, a SU420NET is capable of handling 420 Volt Amps being plugged into the UPS. Determine if your UPS is capable of handling the amount of equipment you have plugged into it.

If the UPS is severely overloaded, the UPS may shutdown and/or the unit’s resettable circuit breaker will trip. The unit must do this in order to protect it’s internal circuitry. This will cause all the equipment connected to the UPS to power off. If the circuit breaker is tripped (it will stick out about a quarter of an inch to a half inch), turn the unit off and push the breaker back in with your finger. Reduce the load and power back up. Ensure that you only have “data-sensitive” equipment plugged into the UPS. Peripheral devices, such as printers, copiers, fax machines, and table lamps, ought to be connected to a separate APC surge strip. This will help to prevent unnecessary loading of the UPS.

3) The UPS exhausted its available battery power – The UPS can only supply battery power for a limited time before the unit must shutdown to protect itself from totally discharging. In some cases, depending on the size of the load and the size of the UPS’s batteries, the UPS may only have a few minutes of battery power. If the UPS didn’t shutdown when it reached a low battery condition, the unit would become incapable of recharging its batteries. Try to determine if the UPS had been on battery shortly before the load shutdown. Keep in mind that while normal power may seem to exist, many power problems are transparent or invisible to a user. These unforeseen power problems, such as voltage waveshape distortion, Harmonic Distortion, and frequency variances, will cause the UPS to go to battery. You may have found that your UPS has been going to battery but only for a very short amount of time. So, what may be happening is that it is going to battery frequently enough that the unit has not had enough time to recharge. Eventually, then, the UPS will shutdown (and drops your load). Try letting the unit recharge by leaving it plugged into the wall and turned on (with no load attached) for 4-6 hours or so.

4) The incorrect serial cable is connected when using APC’s optional shutdown software – The serial cable attached to the Computer Interface (COM) Port on the back of the Smart-UPS is not the correct cable. To verify this, the part number is located on the connector end of the cable that attaches into the UPS COM port. Note: Unix, Novell, OS/2, Windows NT, Windows 95, and Windows 98 all use the 940-0024C serial cable to communicate with PowerChute Plus in Smart signaling. AS/400 uses the 940-0006A cable with the native AS/400 shutdown.

5). An RS-232 serial cable is connected to the UPS, although no UPS shutdown software is installed – Check to see if the serial cable is attached to the Server/Workstation communications port without PowerChute plus installed or running and configured correctly. If PowerChute plus is installed and not configured properly or running, any activity at the Server/Workstation communications port could send a false signal to the Smart-UPS thus causing it to shutdown and reboot.

1. The most common reason for intermittent beeps between 30 seconds to a minute is that the System is detecting a low or weak battery. Follow the link to find an appropriate Replacement UPS Battery for your APC Back-UPS Unit.

2.The most common reason for rapid beeps between every 3 to 5 seconds is the System is powered on and does not detect utility power. Check to see if your UPS has been disconnected from the utility outlet. If the system is plugged in and the outlet is providing power to other devices then your UPS has probably encountered an Internal Fault and it is time to be replaced. Follow the link to find an appropriate Replacement APC Back-UPS Unit.

Other Devices not to connect to a APC Back-UPS are printers, fax machines, and scanners to the APC Back-UPS Battery Backup Outlets. This is because these devices typically draw large amounts of power in a quick amount of time and can overload or drain the Back-UPS power before other equipment can be safely turned off.

RefurbUPS recommends that you have a qualified electrician inspect your wiring for one or more of the conditions listed below.

Reasons why the Site Wiring LED light will illuminate:

1. Overloaded neutral wire.

2. Reversed polarity (hot and neutral wires are reversed).

3. Missing ground wire.

If the outlet that the APC UPS unit is plugged into is not properly grounded or properly wired, the surge protection capability of the unit may be diminished. Therefore, please be sure that the APC unit is only plugged into a properly grounded outlet where the Site Wiring Fault Indicator (SWFI) light is not illuminated.

All of APC’s UPSs with the exception of the Matrix-UPS and the Symmetra Power Array have a small red LED light that is called a SWFI. On some UPS models, this LED is referred to as the Building Wiring Fault Indicator. Both have the same function. On most UPS models, the light is located on the rear of the unit near where the output receptacles are located.

1. APC Back-UPS have stepped approximated sine wave while the APC Smart-UPS have pure sine wave output. This means that APC Smart-UPS provide cleaner power to electronics and will function properly off of a generator. While APC Back-UPS will only marginally adjust input power to output power within a range, meaning sensitive electronics like motors will not function properly and it will not provide good output off of a generator with oscillating sine waves.

2. APC Back-UPS do not support network management cards. APC Smart-UPS do for most models except for example the APC SC series. These Network Management Cards allow for remote shutdown and power control.

3. APC Back-UPS have surge only outlets and battery backup/surge outlets while APC Smart-UPS only has battery backup/surge outlets. This means that APC Back-UPS can have an appliance plugged into a surge only outlet that could draw more power that the VA capacity that the UPS is rated for battery protection, such as a Printer.

These are the primary differences but some models vary in configuration and functionality when looking at the different APC Smart-UPS series.

No Voltage (Blackout): A total loss of utility power.

Low Voltage (Brownout): A decrease in voltage levels.

High Voltage (Over Voltage): A surge is a short-term increase in voltage. A spike is an instantaneous dramatic increase in voltage.

Total Harmonic Distortion (THD): Periodic distortion of the sine wave. Harmonics add to the fundamental frequency in magnitude.

Change in Voltage (dv/dt): Rapidly changing voltage. If the voltage increases or decreases rapidly, the Smart-UPS will transfer to battery because the Smart-UPS does not know how high or how low the voltage will go.

Frequency Changes (Hz): Deviation from the nominal 60Hz in North America.

Before concluding that the Smart-UPS is malfunctioning merely because it is operating on battery, be sure to consider all of the above possibilities.

Smart-UPS, Smart-UPS XL & Smart-UPS Rack Mount

1) Battery connection is loose or disconnected – If the battery connection is not secure the battery power will be unreliable. Verify that the internal battey connections are secure.

2) Unit is Overloaded – Each UPS is limited in the amount of equipment that can be plugged into it. The number in the model number of the UPS tells you the Volt-Amp (VA) limit of your specific model. (The exact model number can be found on a white bar-code sticker on the rear of the unit.) For example, a SU420NET is capable of handling 420 Volt Amps being plugged into the UPS. Determine if your UPS is capable of handling the amount of equipment you have plugged into it.

If the UPS is severely overloaded, the UPS may shutdown and/or the unit’s resettable circuit breaker will trip. The unit must do this in order to protect it’s internal circuitry. This will cause all the equipment connected to the UPS to power off. If the circuit breaker is tripped (it will stick out about a quarter of an inch to a half inch), turn the unit off and push the breaker back in with your finger. Reduce the load and power back up. Ensure that you only have “data-sensitive” equipment plugged into the UPS. Peripheral devices, such as printers, copiers, fax machines, and table lamps, ought to be connected to a separate APC surge strip. This will help to prevent unnecessary loading of the UPS.

3) The UPS exhausted its available battery power – The UPS can only supply battery power for a limited time before the unit must shutdown to protect itself from totally discharging. In some cases, depending on the size of the load and the size of the UPS’s batteries, the UPS may only have a few minutes of battery power. If the UPS didn’t shutdown when it reached a low battery condition, the unit would become incapable of recharging its batteries. Try to determine if the UPS had been on battery shortly before the load shutdown. Keep in mind that while normal power may seem to exist, many power problems are transparent or invisible to a user. These unforeseen power problems, such as voltage waveshape distortion, Harmonic Distortion, and frequency variances, will cause the UPS to go to battery. You may have found that your UPS has been going to battery but only for a very short amount of time. So, what may be happening is that it is going to battery frequently enough that the unit has not had enough time to recharge. Eventually, then, the UPS will shutdown (and drops your load). Try letting the unit recharge by leaving it plugged into the wall and turned on (with no load attached) for 4-6 hours or so.

4) The incorrect serial cable is connected when using APC’s optional shutdown software – The serial cable attached to the Computer Interface (COM) Port on the back of the Smart-UPS is not the correct cable. To verify this, the part number is located on the connector end of the cable that attaches into the UPS COM port.

Note: Unix, Novell, OS/2, Windows NT, Windows 95, and Windows 98 all use the 940-0024C serial cable to communicate with PowerChute Plus in Smart signaling. AS/400 uses the 940-0006A cable with the native AS/400 shutdown.

5). An RS-232 serial cable is connected to the UPS, although no UPS shutdown software is installed – Check to see if the serial cable is attached to the Server/Workstation communications port without PowerChute plus installed or running and configured correctly. If PowerChute plus is installed and not configured properly or running, any activity at the Server/Workstation communications port could send a false signal to the Smart-UPS thus causing it to shutdown and reboot.

1. The most common reason for intermittent beeps between 30 seconds to a minute is that the System is detecting a low or weak battery. Follow the link to find an appropriate Replacement UPS Battery for your APC Smart-UPS Unit.

2. The most common reason for rapid beeps between every 3 to 5 seconds is the System is powered on and does not detect utility power. Check to see if your UPS has been disconnected from the utility outlet. If the system is plugged in and the outlet is providing power to other devices then your UPS has probably encountered an Internal Fault and it is time to be replaced. Follow the link to find an appropriate Replacement APC Smart-UPS Unit.

On-Line: The online LED illuminates when the UPS is supplying utility power to the connected equipment. If the LED is not lit, the UPS is either not turned ON, or is supplying battery power.

AVR Trim: This LED illuminates to indicate the UPS is compensating for a high utility voltage. While the UPS can run in this mode indefinitely without any negative impact on the UPS, the circuit should be checked by a qualified electrician if the utility voltage is consistently high.

AVR Boost: This LED illuminates to indicate the UPS is compensating for a low utility voltage. While the UPS can run in this mode indefinitely without any negative impact on the UPS, the circuit should be checked by a qualified electrician if the utility voltage is consistently low.

- On Battery: This LED illuminates to indicate the UPS is supplying battery power to the connected equipment.

Overload: This LED illuminates to indicate the equipment plugged into the UPS exceeds the total capacity of the UPS. Some of the equipment (the load) on the UPS should be removed or turned off.

Replace Battery: This LED will illuminate when the battery in the UPS has failed the most recent battery self-test. See the APC Knowledge Base Answer ID document #583 to troubleshoot this symptom.

Load: These 5 LEDs represent the percentage of the UPSs capacity that the load is using. Each LED represents approximately 16-17% capacity. For example, if 4 LEDs are lit, approximately 67% of the UPS capacity is being used by the load.

Battery Charge: These 5 LEDs show the approximate charge of the battery in a percent. Each LED represents approximately a 20% charge on the battery. For example, if 4 LEDs are lit, the battery is at 61-80% capacity. If these LEDs are all flashing, see the APC Knowledge Base Answer ID document #1497 to troubleshoot this symptom.

Some of the above LEDs are also accompanied by an audible alarm.

Option 1: Reset the low battery signal time to a lesser value. Take for example a Smart-UPS with 15 minutes of runtime at full charge, and with the low battery signal warning time set for 7 minutes. If runtime remaining is 8 minutes or less , then the battery bar graph LEDs will flash in unison. Try setting the low battery signal warning time to a lesser value through the Configuration menu and then the UPS Shutdown Parameters submenu of PowerChute plus. Two minutes is the lowest setting option available. Please keep in mind that when using PowerChute Business Edition server and console, the low battery signal time is set to 5 minutes and cannot be changed.

Option 2: Reduce the load or replace the battery. The firmware inside a Smart-UPS is designed to last for years, yet the batteries are consumable items. As the batteries age, they lose their ability to hold a charge and therefore available runtime will decrease over time. Once the runtime remaining is within 2 minutes of the low battery signal warning time, the battery charge LEDs will begin to flash and PowerChute software / SmartSlot accessories will report that the “UPS batteries are discharged”, even if the battery is at 100% capacity. In the case of an older unit running with a heavy load, try reducing the attached load. If the unit is an XL (Extended Run) model, then try adding an additional battery pack. Typical battery life is 3 – 6 years. If you have an older UPS, try replacing the battery. XL battery packs and replacement battery cartridges are available for purchase on our website at RefurbUPS.com

Option 3: Perform a Runtime Calibration. This is a manual procedure and should not be confused with the runtime calibration performed through PowerChute software. The batteries inside of the Smart-UPS are controlled by a microprocessor within the UPS. Sometimes it is necessary to reset this microprocessor, especially after the installation of new batteries. Stop the PowerChute software from running and disconnect the serial cable. There must be at least a 30% load attached to the UPS during this procedure, and this load cannot fluctuate more than +/- 5%. This process will cause the UPS to shut off and cut power to its outlets, therefore, attach a non-critical load to the UPS and then force the UPS on battery by disconnecting it from utility power. Allow the unit to run on battery until it turns off completely. Make sure a 30% load is present! Plug the UPS back into the wall outlet and allow it to recharge (it will recharge more quickly turned off and with no load present). Once the unit has recharged, the “runtime remaining” calculation should be more accurate. Remember that if the unit is an older model, then the runtime will not improve significantly. Note: Should the previous steps not resolve the issue contact APC support at 800.890.4272 for further assistance.

Background: An APC Smart-UPS has a microprocessor which calculates runtime primarily based on the load attached to the UPS and on its battery capacity. On the right side of the front display panel there is a vertical graph of five LEDs. Each LED is an indication of battery charge in increments of twenty percent: 20, 40, 60, 80, 100% (bottom to top). For example, if the battery charge is 95%, then only four of the five LEDs are illuminated. To ensure that an operating system receives a graceful shutdown when using PowerChute plus or a SmartSlot accessory, an alert is generated by the Smart-UPS indicating that the UPS has reached a low battery condition. The alert is audible (rapid beeping), visual (flashing battery LED or LEDs), and readable through the graphical interface of PowerChute software (or a native UPS shutdown program within a particular operating system.) In order to calculate this “low battery condition,” all Smart-UPS products have a preconfigured low battery signal warning time of two minutes (this is the factory default setting). There are a total of four user-changeable settings: 2, 5, 7, or 10 minutes. If the low battery signal warning time is set for 2 minutes, then the alerts will activate simultaneously two minutes prior to shutdown. Similarly, if the total runtime for a particular UPS is 30 minutes with a low battery signal warning time set at 10 minutes, then the UPS will run on battery for 20 minutes before the low battery alert begins. Total runtime is primarily based on two factors, battery capacity and UPS load. UPS load and runtime on battery are inversely proportional: as load increases, battery runtime decreases and vice versa. When utility power is lost, the UPS begins discharging the battery in order to support the attached load. Once power returns, the Smart-UPS will automatically begin to recharge its battery.

If the battery fails the test, the “Replace Battery” LED will illuminate. This LED is a warning that the battery may be near the end of its life, and should typically be replaced within 2-4 weeks.

Solution: If the Replace Battery LED is lit, then perform the following steps to determine if the battery does in fact need to be replaced, or if the bad battery indication was due to an invalid test, giving false results.

1. Determine the approximate battery capacity using the battery capacity bar graph LEDs**, which are the row of 5 LEDs on the far right side of the front panel; each LED represents approximately a 20% charge on the battery. If not all of the LEDs are illuminated, then proceed to step 2. If all battery charge LEDs are illuminated, then move to step 3.

2. If all of the battery charge LEDs are not lit, then the battery needs to be charged. If possible, charge the unit for 24 hours or at the very least, charge a standard unit for 3 hours and an XL for 9 hours. The Smart-UPS will charge whether it is on or off. The unit will charge whether there is equipment plugged in or not. However, in environments where the power quality is poor, it is recommend that the unit be off during this charging period. As long as the Smart-UPS is on and able to supply power to your equipment, it is possible that it may switch to battery operation, which will lengthen its recharge time. When all battery charge LEDs are lit, proceed to step

3. If all LEDs do not illuminate after 24 hours, and the unit has been plugged into a good power outlet, there could potentially be a problem with the UPS itself, and it should be replaced.

4. Run a self-test*. A self-test can be initiated by pressing and holding the I/Test button on the front of the UPS for 3-4 seconds. The green On-Line LED should begin to blink, and the amber On-Battery LED will illuminate – this is the indication that the UPS is running the test, which takes approximately 8-10 seconds. At this point, the test will either pass or fail. If the test passes, the Replace Battery LED will no longer be illuminated, and the battery does not need to be replaced; if the test fails, the red Replace Battery LED will illuminate, and the UPS will beep continuously for 1 minute, every 5 hours, until the battery is replaced. * Running a self-test transfers the UPS on to battery power. Normally, this test can be done with the attached equipment still running. However, in instances where the battery has very little power, a transfer may cause a loss of power to the attached equipment. You may want to wait until off-hours to initiate the self-test.

** These LEDs not available on the Smart-UPS 420 and Smart-UPS 620; for these models, start with step 2, and charge the battery for at least 24 hours.

When changing the plug on a Smart-UPS unit you may only go down in Amperage Rating from the Factory Installed Plug. Besides changing a NEMA 5-15P to a locking NEMA L5-15P on Units under 2000 VA. When planning to install a 120V version of the Smart-UPS models 2200 or 3000, care must be taken to ensure that the proper receptacle is available at the installation site, according to the plug that is installed on the UPS. Smart-UPS 2200 rack & tower models (except XL) have a NEMA 5-20P plug while the Smart-UPS 3000 rack and tower models and the Smart-UPS 2200 XL models have a NEMA L5-30P plug. These products cannot be ordered with a different plug, but the user can change the input plug to an appropriately rated one that is compatible with existing site receptacles.

The Smart-UPS 2200 and Smart-UPS 3000 series each ship with a standard plug and cannot be ordered with a non-standard plug. Changing the UPS plug will affect the amount of power the UPS can provide to its loads. Among other things, the available VA and power from a UPS is dependent on the size of its input plug. The higher the nameplate rating of the plug, the more power the UPS can supply to its loads within its own maximum rating. More specifically, UL 1778 limits the input current rating of a UPS to 80% of the plug’s rating. For example, if a UPS has a 20 amp input plug (e.g. NEMA L5-20), UL 1778 requires the current into the UPS should not exceed 16 amps (i.e. 80% of 20) at 120V nominal line voltage. The output of the UPS will then be limited to the input current. Any UPS will need to follow the same guidelines if it carries the UL approval mark.

The following table shows the rating for each plug as well as the different plugs that can be attached to each unit, and the maximum load capacity with each plug option.

| Smart-UPS 2200 Tower, Rack & XL Versions | ||

|---|---|---|

| Plug Types 5-15 5-20 L5-20 L5-30 | Max Input Current 12 Amps 16 Amps 19 Amps** | Output VA 1440 1920 2200** |

| Smart-UPS 3000 Tower, Rack & XL Versions | ||

|---|---|---|

| Plug Types 5-50 L5-30 | Max Input Current 24 Amps 25** Amps | Output VA 2880 3000** |

** Limited by UPS rating, not the input plug.

Any of these plugs are purchaseable through most hardware and/or electrical supply stores. If you need help in determining what these plug types look like, click here to be brought to our Knowledge Base document on plug types.

During shipping, the UPS battery must be disconnected. The replace battery indicator flashing indicates that the battery is not connected. To resolve this issue, check the internal and external battery connections. The steps for battery connection should be listed on the UPS as well as in the user manual.

To check the external battery disconnects, find your model number and follow the directions below:

For Smart-UPS 1000 and 1400 tower models made after 1998: There is a yellow Anderson connector with a wire loop that ships in the box. This needs to be plugged into the back of the unit on the matching Anderson connector.

For Smart-UPS 700 tower models made after 1998: Under the front bezel are two wires, with small yellow connectors. Push these two connectors into each other.

For all Smart-UPS tower models where the model number starts with SUA: There is a black triangular plug in the back of the unit with two pins in it. Flip this plug up and push it into place.

For all other Tower models: There is no external disconnect, you will need to check the internal battery connections. To check the internal connection, open the front bezel and unscrew the metal battery door. Flip the door down and slide ALL of the batteries out. These units will either have red and black terminal wires or an Anderson connector Verify that all the wires are connecting to the proper terminals on the individual batteries, or that the Anderson connector on the battery is attached to the Anderson on the UPS.

For all Rackmount units: Pull off the front bezel. Behind this, there are two wires going into an Anderson connector that needs to be pushed into the matching Anderson connector on the unit. On some RM models, you may need to unscrew the battery door to access this connector.

If you have gone through these trouble shooting steps and you are still getting this indication from the unit, please call our technical support team at 1-800-883-9200

The most reliable way to check compatibility of external battery pack is to consult your Smart-UPS XL Manual. Check if your Smart-UPS XL manual is available in our UPS Manual Section. There are several discontinued Smart-UPS products with external battery packs which may be used with current battery packs. Those units include:

- Smart-UPS 600 Extended Run (AP600XL)

- Smart-UPS 900 Extended Run (AP900XL)

- Smart-UPS 2000 (AP2000, including all wiring device options)

- Smart-UPS 2000 Extended-Run (AP2000XL, including all wiring device options)

- Smart-UPS 2000 Rackmount (AP2000RM, including all wiring device options)

- 208V Smart-UPS 2000 (AP2000M, including all wiring device options)

- Smart-UPS 600XL and Smart-UPS 900XL Options For customers with the Smart-UPS 600XL and Smart-UPS 900XL, the currently manufactured battery pack SU24XLBP will work. No cable adaptor is necessary.

- SU24XLBP

- AP600XL

- AP900XL

Smart-UPS 2000 Options: The discontinued models have two components; an Electronics Unit(PE) and a Battery Pack(BP). Currently built Smart-UPS products are one piece. The original battery pack’s part number is AP2000BP for the tower units. For the RM version, the part number is AP2000RMBP. For the XL version, the part number is AP2000XLBP. Neither the electronics unit nor the battery packs are currently produced; however, there are circumstances where a customer may wish to replace a battery pack or add another for additional runtime. The Smart-UPS 2000 tower and rackmount models are designed to have one (1) battery connected. These units do NOT have extended-run functionality. They have a red battery connector. Therefore, only one battery pack may be connected to the electronics unit. The SU48BP is a battery pack designed to provide extra runtime for several in-production models; however, it will also work with the following older Smart-UPS:

- SU48BP

- AP2000

- AP2000RM

- AP2000M

Smart-UPS 2000XL Options: The Smart-UPS 2000 extended-run(XL) allows the user to daisy-chain battery packs together to provide the customer with increased runtime. These units have a gray battery pack connector. (Because the XL units have a more robust battery charger than standard models, a maximum of ten additional batteries can be added). The SU48XLBP and the SU48RMXLBP are extended-run battery packs for in-production models. The connector is blue. In order to use with the following models, a special blue to gray patch cable manufactured by APC is required; part number SU037.

- SU48XLBP

- AP2000XL

- SU48RMXLBP

- AP2000XL

There is only one serial port on each Smart-UPS model UPS that operates in “Smart” signaling mode. All Smart-UPS models 700 and higher also have a Smart Slot available for optional accessories. For Smart-UPS models 700 and higher, there are two options for shutting down multiple servers when a UPS goes to battery.

The first option is to purchase an APC Interface Expander – part number AP9607 (provides additional 2 ports) or AP9207 (provides additional 7 ports). You may also daisy chain up to four of the AP9207s, allowing 32 total servers to be monitored off of one UPS. This solution requires the purchase of additional APC basic signaling serial cables – part number 940-0020.

This solution is the communication across a physical serial connection between the UPS and attached servers for use with our PowerChute Business Edition (PCBE) software. To check which operating systems are compatible with PCBE, please follow this link If you are using a version of Unix that is not supported by PCBE, but is supported by PowerChute Plus, you would need to purchase the AP9823 simple signaling cable for Unix.

If you prefer not to have additional serial cables cluttering your server room, you could opt for the network shutdown solution. This option requires the purchase of APC part #AP9617, AP9618 or AP9619 – the Network Management Card. By installing the Network Management Card (NMC) into the UPS and configuring an IP address for the card, you make the UPS a node on your network. You will then download the free PowerChute Network Shutdown (PCNS) software from www.apc.com/tools/download and install it on any computer you wish to shutdown gracefully during a power event. Operating system compatibility with PCNS is also listed on our software downloads page.

When the UPS goes to battery, it broadcasts a message to any computer with PCNS installed. Options and parameters are easily configured through the web interface. You can remotely configure the servers for shutdown and remotely monitor the UPS with the NMC option.

Answer: The Smart-UPS detects line voltage distortions such as spikes, notches, dips, and swells, as well as distortions caused by operation with inexpensive fuel-powered generators. By default, the UPS reacts to distortions by transferring to on-battery operation to protect the equipment that you are plugging into the UPS. Where power quality is poor, the UPS may frequently transfer to on-battery operation. Battery longevity and service life of the UPS may be conserved by reducing the sensitivity of the UPS, as long as your equipment can operate normally under the conditions detailed below. Any type of voltage disturbance includes; High/Low/No RMS Voltage, Total Harmonic Distortion(THD), Change in Voltage over Time(dv/dt), Frequency (Hz) out of tolerance.

To change the sensitivity of the UPS, press the small, white “sensitivity” button* on the rear of the UPS. Use a pointed object (such as a pen) to do so. The default setting is “high”; press the button once to set the sensitivity to “medium”, and press it again to set it to “low”; pressing it a third time will set it back to “high”. The sensitivity setting change will take effect immediately. The green LED next to the button is a sensitivity setting indicator – brightly lit is “high” sensitivity, dimly lit is “medium”, and off is “low” sensitivity.

High Sensitivity Mode

In the event of any type of voltage disturbance, the UPS will transfer to battery power and watch the AC line until it can transfer back to line. The transfer time in this mode depends on how far the line voltage deviates from the sinewave reference.

Medium Sensitivity Mode

In the event of a RMS voltage-out-of-tolerance(High/Low/No) and RMS-rate-of-change disturbances(dv/dt) in the line voltage, the UPS will transfer to battery power and watch the AC line until it can transfer back to line. In this mode the transfer times are longer but still within acceptable limits to insure the continuity of a computer’s operation.

Low Sensitivity Mode

In the event of a RMS voltage-out-of-tolerance disturbances(High/Low/No) in the line voltage, the UPS will transfer to battery power and watch the AC line until it can transfer back to line. In this mode the transfer times are longer but still within acceptable limits to insure the continuity of a computer’s operation.

There are several differences between APC Back-UPS and APC Smart-UPS models.

1. APC Back-UPS have stepped approximated sine wave while the APC Smart-UPS have pure sine wave output. This means that APC Smart-UPS provide cleaner power to electronics and will function properly off of a generator. While APC Back-UPS will only marginally adjust input power to output power within a range, meaning sensitive electronics like motors will not function properly and it will not provide good output off of a generator with oscillating sine waves.

2. APC Back-UPS do not support network management cards. APC Smart-UPS do for most models except for example the APC SC series. These Network Management Cards allow for remote shutdown and power control.

3. APC Back-UPS have surge only outlets and battery backup/surge outlets while APC Smart-UPS only has battery backup/surge outlets. This means that APC Back-UPS can have an appliance plugged into a surge only outlet that could draw more power that the VA capacity that the UPS is rated for battery protection, such as a Printer.

These are the primary differences but some models vary in configuration and functionality when looking at the different APC Smart-UPS series.

The only difference between a SmartUPS and a SmartUPS Net unit is that the Net unit when purchased new, comes with the PowerChute software. In regards to Refurbished units, both are the same. RefurbUPS does not send out any additional software as it is a free download from APC’s website.

The Main difference over all these models is that APC Smart-UPS SUA have USB ports and APC Smart-UPS SU do not. There are other differences between specific models including Extended Run Battery Packs not being interchangeable between series.

The main difference is that Smart-UPS SMT are the newer model that has an LCD control screen that allows for changing settings without the use of a workstation and communication cable.